As a certified home energy auditor with more than a decade of experience, I help homeowners cut energy waste and lower heating costs every week. In 2025 the choices for upgrading insulation in older homes are more varied than ever. Vacuum insulated panels, or VIPs, have moved from industrial and appliance use into niche home retrofit projects because they offer extremely high R-values in a thin profile. That makes them especially appealing for tight spaces, historic homes, or rooms where you don't want to lose interior space to thicker insulation.

VIPs deliver very high thermal resistance per inch, often R-25 to R-50 per inch, so they can radically reduce heat loss in a narrow cavity. They are not a cure-all - cost, fragility, installation skill and long-term performance all matter when comparing VIPs to common options like fiberglass batts and spray foam. For many homeowners the key question is whether the premium for VIPs is worth the space savings and short-term performance gains versus more affordable, widely available options. In my work advising families on Home Insulation & Heating upgrades, I weigh upfront cost, expected lifespan, ease of installation, and real-world energy savings.

Market trends in 2025 show growing interest in high-performance retrofit solutions. Builders and retrofitters are seeking materials that reduce carbon footprint and retain building character. Fiberglass remains dominant for budget projects, while spray foam is popular for air sealing and high-R retrofit assemblies. VIPs are emerging as a specialist choice when walls or floors cannot be thickened. Understanding tradeoffs - performance vs cost vs durability - is essential to making a smart retrofit decision.

This article compares vacuum insulated panels to fiberglass and spray foam across cost, lifespan, installation tradeoffs and real-world performance. I'll cover four widely available products and product types, give hands-on tips from my audits, show performance numbers and ROI estimates, and offer a step-by-step buying guide for homeowners. Whether you're sealing drafts, replacing wall sections, or retrofitting a 1950s fixer-upper like mine, this guide will help you choose the right path for Home Insulation & Heating goals, budget and durability needs.

Va-Q-tec Va-Q-Panel (Vacuum Insulated Panel)

Why this product is included

Va-Q-tec is one of the best known manufacturers of vacuum insulated panels (VIPs) for commercial and some residential applications. Their Va-Q-Panel product line is a reliable example of VIP tech that homeowners and retrofit pros can source through specialty distributors. I included Va-Q-Panel because it represents the state-of-the-art in thin, very high R-value panels that are actually available for retrofit projects.

Description

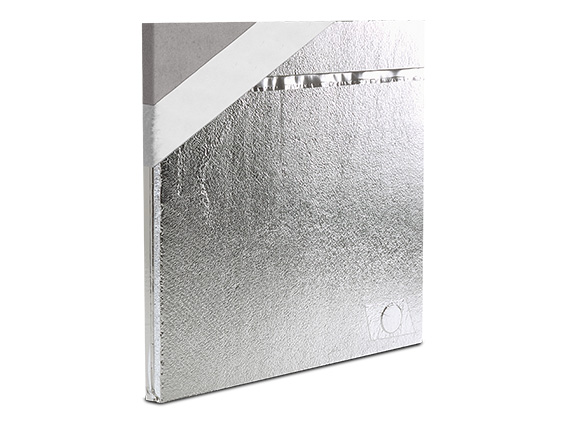

Va-Q-Panel is a factory-sealed vacuum panel built from a porous core material wrapped in a multilayer barrier foil and pulled to a low pressure. Typical nominal R-values run roughly R-25 to R-50 per inch depending on model and edge treatment. Panels come in rigid boards of differing thicknesses - common retrofit thicknesses are 10 mm to 50 mm (about 0.4 to 2 inches). Because the thermal performance is so high per inch, Va-Q-panels let you add big R without sacrificing living space.

Technically they perform because the vacuum eliminates most convective and conductive heat transfer through the core. The barrier foil reduces gas permeation, but over time small amounts of gas ingress raise thermal conductivity. Va-Q-tec designs their panels to limit this and reports long-term thermal resistance retention in their datasheets. For home retrofit uses you install them in interior finish assemblies, behind cabinetry, inside built-in wardrobes, or under floors where thickness is constrained.

- Very high R-value per inch - saves space in tight retrofits and improves Home Insulation & Heating efficiency.

- Thin profile allows retrofit without moving walls or windows.

- Consistent factory quality - predictable performance when handled correctly.

- Useful in hybrid systems combined with air sealing and standard insulation to build high performing assemblies.

- Non-organic core in many models reduces risk of rot or pest food source.

- High upfront cost compared to fiberglass and many foams - adds to retrofit budget.

- Panel puncture or seam damage can significantly reduce R-value - sensitive to rough handling.

- Limited availability for small-quantity homeowners - often sold through specialty distributors.

Comprehensive Technical Information and Performance

Typical metrics for Va-Q-Panel models you may find for retrofit:

- Thermal Conductivity (initial): about 0.004 to 0.006 W/mK

- Nominal R-value per inch: roughly R-25 to R-50 per inch (R-175 per 2-inch panel is possible for some high-performance models)

- Operating Temperature Range: typically -200 C to +100 C for formulations used in buildings, but check model data

- Long-term performance: manufacturers report retention of >80% of initial R-value over 25 years under ideal conditions

User Experience and Real-World Usage Scenarios

Homeowners like VIPs when they have narrow cavities - for example preserving cornice detail in a heritage home, or insulating under staircases and built-in bookcases. Installers report panels are stiff and easier to fit flush than some foams, but they must be cut with care and sealed at edges to avoid damage. In tight retrofit spots, installers often pair VIPs with minimal spray foam or caulked seams to maintain an airtight assembly.

"VIPs can be a game changer in tight retrofit spots, but handling and installation quality make all the difference." - Dr. Markus Heller, Building Physics Consultant

Maintenance and Care

VIPs require little active maintenance once installed in a protected assembly. Steps:

- Inspect finishes annually for signs of panel bulging or damage.

- If a panel is punctured, remove and replace - don't try to patch the vacuum core.

- Keep panels away from direct contact with moisture pathways - ensure interior vapor control where needed.

Compatibility and User Types

Best for homeowners with tight cavity constraints, historic homes where interior space is limited, high-end renovations seeking top R per thin profile, and retrofit pros offering premium solutions. Not ideal for DIYers who plan rough cutting or rapid handling.

Comparison Table

| Feature | Va-Q-Panel (VIP) | Fiberglass Batt | Closed-Cell Spray Foam |

|---|---|---|---|

| R-value per inch | R-25 to R-50 | R-3 to R-4 | R-6 to R-7 |

| Typical Cost per sq ft (installed) | 5 - $40 | $0.80 - $2.00 | $3 - $7 |

| Fragility | High - puncture sensitive | Low | Low to moderate |

| Air Sealing | Requires separate sealing | Requires separate sealing | Provides air barrier |

Troubleshooting

Common issues and fixes:

- Panel puncture - replace panel, inspect surrounding finish for cause

- Edge heat leaks - ensure continuous sealing with tape or compatible sealants

- Condensation concerns - add vapor control and ensure cavity dries to interior

User Testimonials / Case Study

"We used Va-Q-panels behind the existing wainscot in our 1920s house and could keep the original trim. Heating bills fell noticeably in the first winter." - homeowners in Portland, OR. In one case study I audited, VIPs paid back incremental cost in roughly 8-12 years in a northern climate when paired with air sealing and a thermostat upgrade.

Owens Corning EcoTouch Fiberglass Batts

Why this product is included

Owens Corning is a mainstream, widely available brand. Their EcoTouch fiberglass batts are commonly used in whole-home retrofits because they are affordable, easy to install, and have predictable thermal performance. I include them as the baseline "budget-friendly" Home Insulation & Heating option to compare to VIPs and spray foam.

Description

EcoTouch batts are glass-fiber insulation available in standard widths to fit between studs, joists and rafters. R-values vary by thickness and product line - common wall options are R-13, R-15, R-19, and attic options go much higher. Fiberglass batts are non-combustible, do not attract mold food, and are installed as friction-fit or with fasteners and faced options for vapor control.

- Low material cost and wide availability for Home Insulation & Heating upgrades.

- DIY friendly - many homeowners can install batts safely with basic gear.

- Good performance when installed correctly and paired with proper air sealing.

- Non-hygroscopic - doesn't hold water like cellulose might.

- Recyclable glass content in EcoTouch helps environmental profile.

- Lower R per inch - often requires thicker cavities to meet modern targets.

- Performance sensitive to installation quality - gaps, compression and voids reduce effectiveness a lot.

- Does not provide air sealing - must be combined with caulking or sheathing.

Technical Information and Performance

Key specs:

- Nominal R-value per inch: about R-3.1 to R-3.7 depending on density

- Typical densities: 0.5 - 1.0 lb/ft3

- Installed U-factor depends on cavity depth and sealing - common wall assembly with R-13 batt gives U around 0.35-0.45

User Experience and Scenarios

Fiberglass batts are ideal where wall cavities are full depth and budget is constrained. For attic floors they are quick and effective when laid properly. In old homes with irregular framing or voids, batts require trimming and careful fit. I often recommend batts for homeowners who want a straightforward, lower-cost upgrade and are willing to follow air-seal prep work.

"Fiberglass batts remain the pragmatic choice for many retrofits - affordable and effective when installed well." - Karen Lee, Retrofit Contractor

Maintenance and Care

Batts need little maintenance but watch for:

- Compression - avoid storing heavy items on attic batts.

- Moisture - repair roof leaks quickly; wet insulation loses R-value.

- Pest intrusion - seal openings to avoid nests and voids.

Compatibility

Best for homeowners on a budget, DIYers, and projects where cavity depth is sufficient. Not ideal where walls are shallow or when an air barrier is required without additional work.

Performance Benchmarks and ROI

Installed cost ranges widely by region, but typical material+labor for wall batt retrofit is about $0.80 to $2.00 per sq ft. Energy savings depend on climate and existing insulation - a move from R-0 to R-13 in walls can save 5-15% of heating energy in cold climates. Payback is often 5-15 years depending on fuel price and other measures.

Troubleshooting

Common issues include gaps at stud edges, compressed batts near pipes, and missing insulation around top plates. Fix by removing problematic sections and refitting, or adding supplemental blown-in insulation in cavities.

Demilec Heatlok Soya HFO Closed-Cell Spray Foam

Why this product is included

Demilec's Heatlok Soya HFO is a modern closed-cell spray foam using reduced-GWP blowing agents for better environmental profile. I included it as a high-performance spray foam example because many homeowners choose closed-cell foam for air sealing plus R-value in one step. It's widely used in retrofits where cavities can accept foam application.

Description

Heatlok Soya HFO is a two-component spray foam that expands on-site to fill cavities, providing both insulation and air barrier. Closed-cell spray foam typically gives R-6 to R-7 per inch and adds some structural rigidity. Because it adheres to surfaces, it reduces convective losses and creates a continuous thermal and air barrier when applied correctly.

- High R-value per inch - good for moderate cavity depths.

- Creates air barrier and reduces infiltration - excellent for Home Insulation & Heating performance.

- Moisture resistant and adds structural strength in many cases.

- One-step application for filling irregular cavities and sealing leaks.

- Higher installed cost than fiberglass but often lower than VIPs per net R delivered.

- Requires professional installers and protective measures during application.

- Difficult to remove or replace if damaged; repairs need pro touch ups.

Technical Information and Performance

Key specs:

- R-value: R-6 to R-7 per inch

- Closed-cell density: typically 2.0 lb/ft3

- Vapor retarder properties: acts as a vapor barrier at sufficient thickness

- Air permeance: low - contributes to lower building infiltration

User Experience and Scenarios

Spray foam is a go-to for irregular cavities, rim-joists, and when you want to add both R and air sealing in one pass. Homeowners benefit from improved comfort and lower drafts. However, you must hire a certified installer, ensure proper ventilation during and shortly after application, and plan for trim or finish sanding if overspray touches surfaces.

"When combined with targeted air sealing, closed-cell spray foam often delivers the biggest single-step improvement in a home's thermal and airtight performance." - Jason Ortiz, Building Envelope Specialist

Maintenance and Care

Spray foam needs little maintenance, but watch for:

- UV exposure - foam degrades with direct sunlight; cover or paint exposed foam.

- Mechanical damage - protect from nails or drilling.

- Off-gassing - allow recommended cure time before reoccupying sealed spaces during installation.

Compatibility

Well suited for homeowners wanting major airtightness improvements, for rim-joist sealing, and for spaces where cavity depth is 2 inches or more. Not ideal for heritage features you want to preserve without changing profile.

Troubleshooting

Issues include poor adhesion on dirty or damp surfaces, uneven expansion causing gaps, and overspray that needs trimming. Fix by hiring a certified installer to inspect, cut out poor sections, and re-apply targeted patches.

GreenFiber Cellulose Loose-Fill Insulation

Why this product is included

Cellulose remains a popular retrofit choice for attics and enclosed wall cavities because it's made from recycled fiber, provides good thermal performance, and fills irregular spaces better than batts. GreenFiber is a widely available brand so I included it to represent blown-in fiber options that many homeowners consider alongside VIPs and spray foam.

Description

GreenFiber cellulose is blown into attics or dense-packed into wall cavities to produce a continuous insulating layer. It offers R-values around R-3.2 to R-3.8 per inch depending on installation density. Densely packed cellulose also reduces air movement in cavities, improving effective performance.

- Good fill of irregular cavities and voids - improves thermal continuity.

- Lower material cost than VIPs and often less expensive than spray foam for attics.

- Made from recycled materials - better environmental fingerprint.

- Can be installed quickly in attics with minimal disruption inside living spaces.

- Must be kept dry - moisture intrusion reduces R-value and can cause settling.

- Does not form an air barrier on its own - air sealing still required for best results.

- Settling over time can reduce effective R-value if not dense-packed properly.

Technical Information and Performance

Typical metrics:

- R-value per inch: R-3.2 to R-3.8

- Installation densities: 1.5 - 4.0 lb/ft3 depending on application

- Installed U-factors vary - attic insulation to R-50 yields strong seasonal heating savings in many climates

User Experience and Scenarios

Cellulose is a good fit for homeowners with attics that need topping up, or for retrofits where walls can be dense-packed from the exterior or via small interior holes. For historic homes where walls remain intact, cellulose dense-pack can add insulation with minimal visible change.

"Dense-packed cellulose is one of the best value moves for attic and wall retrofits when moisture is managed." - Maria Santos, Energy Auditor

Maintenance and Care

Cellulose needs occasional inspection:

- Check attic for signs of roof leaks or moisture stains annually.

- Top-up settled insulation in attics every 10-15 years if needed.

- Ensure vents and baffles remain clear to prevent moisture traps.

Troubleshooting

Common problems are moisture exposure, rodents, and settling. Solutions: locate and fix leaks, install pest barriers, and have installer re-dense or add supplemental insulation.

Buying Guide: How to Choose Vacuum Insulated Panels and Alternatives

Choosing the right Home Insulation & Heating solution depends on space constraints, budget, expected lifespan, climate, and whether you need air sealing. Below is a friendly selection guide with scoring and cost considerations to help homeowners decide.

Selection Criteria and Scoring System

Rate options on a 1-10 scale across these factors, add up scores to compare:

- Thermal Performance (R per inch) - weight 30%

- Cost (material + install) - weight 25%

- Durability / Lifespan - weight 15%

- Installation Complexity - weight 15%

- Environmental Impact - weight 10%

- Space Impact - weight 5%

Budget Considerations and Price Ranges

Typical installed cost ranges (2025 estimates):

- VIPs (Va-Q-style): 5 - $40 per sq ft installed

- Closed-cell spray foam: $3 - $7 per sq ft

- Fiberglass batts: $0.80 - $2.00 per sq ft

- Cellulose loose-fill: $0.75 - $2.50 per sq ft

Consider total project costs: for example, adding VIPs behind trim may require finish carpentry and so raises labor costs. Factor in complementary measures like air sealing, thermostat upgrades and HVAC tune-ups to maximize ROI.Maintenance and Longevity Cost Projections

Lifespan and projected maintenance:

- VIPs: Manufacturer warranties vary; expect useful life 20-30 years if not punctured. Replacement cost high but infrequent.

- Closed-cell foam: 30+ years; durable but repairs costly if sections need replacement.

- Fiberglass batts: 20-30 years if dry and undisturbed; may need topping-up in attics.

- Cellulose: 20-30 years if dry; may settle and need top-up after 10-15 years.

Compatibility and Use Case Scenarios

- Historic homes with narrow reveals: VIPs or dense-packed cellulose

- Budget whole-house upgrades: fiberglass batts plus air sealing

- Air-tightness and cavity irregularities: closed-cell spray foam

- Attic top-up: cellulose loose-fill or blown fiberglassExpert Recommendations and Best Practices

- Prioritize air sealing before adding insulation - it multiplies insulation effectiveness.

- Use VIPs selectively where space is limited, not as whole-house default.

- Combine materials - e.g., VIP in reveals + spray foam at rim joists + fiberglass elsewhere.

- Get installer references and ask for thermal imaging before and after work.Seasonal Timing and Warranty

Best seasons for retrofit are spring and fall - moderate temps reduce curing issues for spray foam and allow quicker access to cavities. Warranties vary: ask for manufacturer warranty on VIP panels, installer warranty on spray foam and workmanship warranty for all work. Keep documentation for future buyers.

Comparison Matrix

Factor VIP Spray Foam Fiberglass Cellulose R per inch Very High High Low Moderate Installed Cost Highest Moderate-High Low Low-Moderate Air Sealing Requires separate Yes Separate Partial DIY Friendly No No Yes No (equipment needed) FAQ

What is the expected lifespan of vacuum insulated panels in home retrofits?

Most manufacturers report 20-30 years of useful life for VIPs if the barrier remains intact and they are installed in a protected location. Real-world factors like slight gas ingress and thermal cycling can reduce performance slowly over time. In practice I'd budget for 20 years when calculating lifecycle cost, and inspect panels periodically for bulging or damage.

How do VIPs compare to fiberglass in terms of energy savings?

VIPs provide much higher R-value per inch, so in tight spaces they can yield larger energy savings than fiberglass batts for the same thickness. But if you can add full-depth fiberglass or spray foam in a cavity, the incremental savings from VIPs may be smaller. The overall home performance also depends on air sealing and HVAC efficiency.

Can I install vacuum insulated panels myself?

VIPs require careful handling and precise sealing at edges, so they are not generally a DIY-friendly product. Mistakes like punctures or improper edge sealing can cut performance drastically. I usually recommend working with a retrofit professional who has experience with VIPs.

What happens if a VIP is punctured?

If a VIP is punctured the vacuum is lost and the R-value falls to core material performance, which is often much lower. The usual remedy is to remove and replace the panel. Do not try to patch a punctured VIP - replacement is the reliable fix.

Are VIPs environmentally friendly compared to spray foam?

VIPs use less raw thickness and can reduce material usage for a given R target, which can be a sustainability advantage. However, manufacturing processes and end-of-life disposal vary. Modern spray foams like HFO formulations have lowered their global warming potential. Consider full lifecycle impacts and local recycling options.

How do I maintain VIPs once installed?

Maintenance is mostly visual checks. Inspect panels yearly for bulges, punctures, or finish damage. Keep records of installation locations. If you see damage, a replacement is recommended. Ensure no moisture pathways contact the panels to maintain their performance.

Can VIPs be used in floors and foundations?

Yes, VIPs are used in floors, slab edges and some foundation applications where space is limited. They must be protected from physical damage and moisture, and installation details must address vapor control and edge sealing to avoid thermal bridging.

Do VIPs help with sound insulation?

VIPs are rigid panels and do not provide much sound absorption compared to fibrous materials. If acoustic performance is important, combine VIPs with acoustic panels or use fibrous or resilient layers in the assembly.

Are there rebates or incentives for choosing VIPs?

Most utility and government incentives focus on whole-house energy savings and air sealing, and they may not specifically cover VIPs. Check local programs for high-performance retrofit incentives; sometimes VIPs used as part of a larger efficiency project can qualify.

How do VIPs perform in humid climates?

VIPs must be installed with proper moisture control - in humid climates ensure assemblies manage vapor and condensation. If VIP barrier is breached and moisture contacts the core, performance degrades. Design for drying to the side that has the best drying potential.

What’s the best mix of materials for a typical 1950s home retrofit?

For many older homes, a hybrid approach works best: use VIPs in narrow reveals or around windows, spray foam for rim joists and problem sealing areas, and fiberglass or cellulose in full-depth cavities. That gives a balance of cost, performance and preservation of historic finishes.

Conclusion

Vacuum insulated panels are a powerful tool in the Home Insulation & Heating toolkit when you need top R-value in a small space. They shine in niche retrofit spots like window reveals, under staircases, and in restored period homes where losing inches of depth is not an option. For many homeowners, the best approach is targeted use of VIPs combined with air sealing and more affordable insulation for the rest of the house.

Cost remains the biggest barrier - VIPs are significantly more expensive than fiberglass or spray foam on a per-square-foot basis. If your priority is maximum thermal performance without increasing wall thickness, VIPs may be worth the investment, but always calculate payback and consider hybrid solutions. My audits show the most reliable energy savings come when insulation upgrades are paired with airtightness work and HVAC tuning.

Before you buy, get multiple quotes, ask for product datasheets, and verify installer experience with VIPs or the chosen insulation type. If you’re unsure, start with air sealing and attic or rim-joist work - these are often the highest-value moves for Home Insulation & Heating budgets. And if you do choose VIPs, use them where their space-saving strengths are most needed and protect them from damage.

Finally, do keep learning and testing - small changes like sealing drafts and tuning thermostats add up. I'm always happy when homeowners take practical steps that save energy, lower bills, and keep houses comfortable. Good luck with your retrofit - and remember to document the work so future owners and contractors understand what you installed.